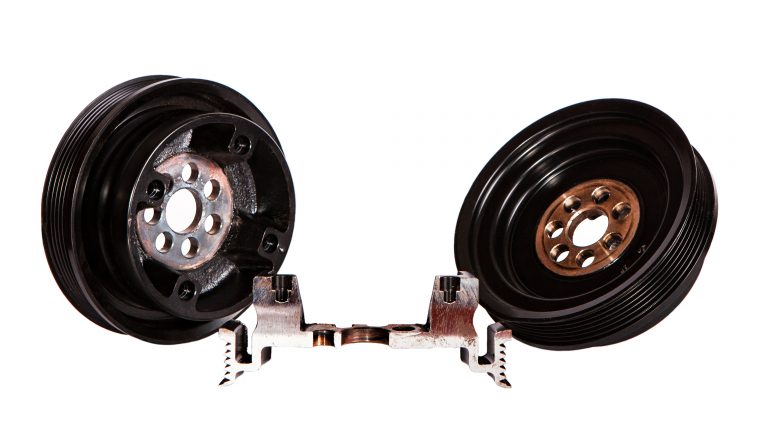

Hardening of rollers and pulley raceways

Induction hardening of rollers allows hardening of external or internal sliding surfaces. The hardening of external surfaces can be carried out using inductors with the workpiece centrally positioned inside. In this solution, after heating, the coolant can be applied by spraying, as in shaft hardening, or by completely immersing the roll in water or oil.

In internal bore hardening, inductors are used which shape the magnetic field around their outer contours. The cooling solutions are analogous to those used in the hardening of external roller parts.

In either case, the roller should be put into a rotating motion to uniform the temperature distribution.

Another solution, used in the case of large rolls, is zone heating with a small-sized inductor with a spray nozzle located in its immediate vicinity. The station in this case must be equipped with a turntable ensuring constant rotational movement of the roll, with rotation adapted to the heating process.

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

- About Us

- Products

- Technologies

- Hardening

- Soldering

- Carbide brazing

- Brazing of CO radiators

- Brazing of electrotechnical components

- Hard soldering of silver contacts

- Brazing of inductors

- Brazing of water and gas connections

- Soldering of titanium

- Soft soldering of electronic components

- Soft soldering of high frequency connectors.

- De-soldering of components for metal recovery

- Melting of metals

- Forging and forming

- Other technologies

- Continuous drying of paints and coatings

- Softening of ultrasonic seams

- Vacuum spraying

- Heating of anodized parts before bending

- Heating pipes before bending

- Pre-weld heating

- Preheating of wire ropes

- Connections based on temperature expansion

- Fusing inserts into plastics

- Induction welding

- Induction welding of seamed tubes

- Diffusion welding

- Thermal dimension calibration

- Letting go / relaxing

- Melting reactive metals

- Powder sintering

- Services

- Gallery

- Contact